Powerful databases are created to handle and track inventory products in all enterprises, large and small. It’s vital for them to keep track of both slow-moving and high-demand items in order to correctly adjust inventory levels. To accomplish this, they use dedicated database systems. These systems are known as inventory management solutions.

Let’s see what is all about

What Is Inventory Management Software?

Inventory management software streamlines the processes required to properly maintain inventory, manage to reorder, and update accounting data by automating components of inventory and warehouse management.

“We refer to this software as mission-critical.’ You’re in serious trouble if it doesn’t work for a few hours.”

The tracking of products entering and exiting a company’s facilities is made easier with an inventory management solution. It practically covers everything, from production through warehousing, transportation, and retail. It allows us to follow the stock’s every move.

Read Also – Top On-demand App Ideas to Start Money Making Startup in 2022

How does it work?

Inventory management software is used to manage complex inventory duties as disconnected software or as part of a business ERP system. It is used in conjunction with RFID tags and barcode scanners to capture and store order item details. Warehouse personnel can quickly discover order goods and update inventory tally using such methods. This technology shines in the real world thanks to its capacity to track items in real-time.

In a nutshell, Inventory management software streamlines and automates your warehouse processes. This saves you time, energy, and important resources that would otherwise be spent on supply chain operations.

Where are companies investing heavily to improve their inventory management practices?

- Despite the pandemic’s effects, the global supply chain management business is expected to grow to $37.41 billion by 2020. The CAGR is expected to be 11.2 percent between 2020 to 2027.

- SCM is expected to earn approximately 8.5 million USD in income globally by the end of 2022, according to experts.

- These graphs show how technology has altered this once-simple supply chain management.

So by going through these points we are ready to make this App

Benefits of Inventory Management Software Development

You can make plans with a good inventory management system. It is possible to maintain a close eye on product stock levels, as well as manage and reorder them as necessary. The following are some of the advantages of using an inventory management system:

Well-organized Stock Operations

You can keep track of all of your available products with inventory management software development. You can save a great amount of time and effort using it. It takes much longer to do it manually by going to the stock site and manually inspecting each and every stock.

Order Frequency

Maintaining a minimal amount of stock is a bad idea for the company’s operations. You can keep track of all of your inventory and reorder as needed with an Inventory Management System.

Customer Satisfaction

Customers can be retained if a company’s product delivery, quality, and services are maintained. When you provide the product on time and give the service they require, they are satisfied. Any consumer can follow the shipment of their goods and prevent being notified of product unavailability owing to the great tracking system.

Read More-

Lower risk of overselling

Overselling is one of the most difficult issues that internet merchants confront. Customers are usually unsatisfied as a result of this, as well as a loss of control and suspension from marketplaces.

however, if you use an inventory management system, you can prevent all of these issues. With the use of such software, you can easily sync your inventory and orders across all of your online platforms and marketplaces. This will ensure that your stock levels are changed when you make a sale. It’s also quite useful for stock management.

Improved Sales & Productivity

By maintaining a complete inventory of all stock. A company reduces customers. And the likelihood of making common errors like counting or having an erroneous amount of products on stock. With the help of Inventory Management Software, you can easily meet the delivery requirements. To get the most out of it, hire a Top software development company.

Centralized Storage

Managing commodities and products across several locations is difficult. It’s also difficult to keep track of the inventory and deliver the correct product.

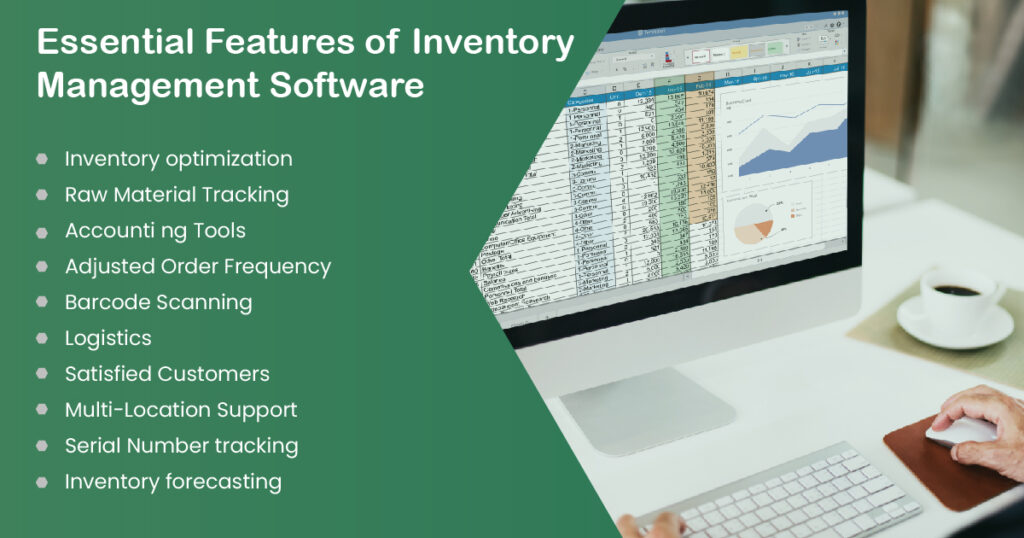

Essential Features of Inventory Management Software

Inventory optimization

An inventory management system can also help you know your inventory. Not only that, but it also helps with inventory control. And it also helps in evaluating the moment at which products are changed in that way.

Raw Material Tracking

These features determine whether it is a raw material to start a new job in the manufacturing process.

Accounting Tools

A user can have a complete evaluation of stocks in production using techniques. It is like cost layering, measures, overheads allocation, and news.

Adjusted Order Frequency

Overstocking is significantly worse for a firm than a supply shortage. With a thorough inventory management system, you can keep track of your stock supply and fillup it up as needed. This will reduce product waste, which would otherwise result in large financial losses.

Barcode Scanning

An inventory manager can scan a product’s barcodes with this feature. This type of electronic data transmission can also be accomplished with Smartphones, obviating the need for expensive hardware.

Logistics

Transportation data analysis and trackers, for example, are third-party logistics elements that improve product and material transportation transparency. So, users and warehouse managers can simply track the shipment’s location to find out when it will arrive.

Satisfied Customers

Your customers will be delighted with accurate responses, prompt delivery, and personalized services. They will be able to track the status of their shipment. And also will not be at risk of receiving a notice of unavailability of product.

Multi-Location Support

Many businesses retain their inventory in many warehouses. Therefore warehouses are ready to track and control.

Serial Number tracking

Inventory workers can update inventory by using item serial numbers with this ability.

Inventory forecasting

To avoid out-of-stock and overstock situations, this function estimates the future demand of items using Artificial Intelligence and predictive analytics.

The Cost to Develop an Inventory Management Software

The type of features you require determine the maximum costs for developing inventory management software. To accomplish so, you must first understand the needs of your firm. Once you’ve figured out everything you need, you’ll be able to determine a final budget.

It’s up to you to decide whether a basic introductory system will be enough or whether a fully functioning inventory management system with ERP software is required. You’ll be able to create a reasonable budget for your system according to your requirements.

If you want to build it from the ground up, software like Inventory Management System can cost anywhere from $15000 and $30,000, depending on the number of panels, features, technology, and functionality.

Wrapping up

Inventory management software development is crucial for every company. It is especially those in the retail and industrial industries, as confirmed by the previous discussion. It makes it easy to track inventory.

Serva Applabs, the Best inventory management software, provides inventory counting and stock replenishment services. Including data aggregation platforms & depository. Our inventory management software syncs inventory across many channels. And locations via EDI interfaces and implementation services, reducing repetition and errors. Allow us to help you create your own inventory management software.